About product

200ton

| Model | W(mm) | H(mm) | D(mm) |

| DRⅡ-15F(-HG) | 760 | 1696 | 525 |

| DRⅡ-25F(-HG) | 760 | 1845 | 525 |

| DRⅡ-50F(-HG) | 830 | 1965 | 525 |

| DRⅡ-75F(-HG) | 830 | 2245 | 525 |

Combined dryer & loader unit with pursuing space-saving and energy-saving

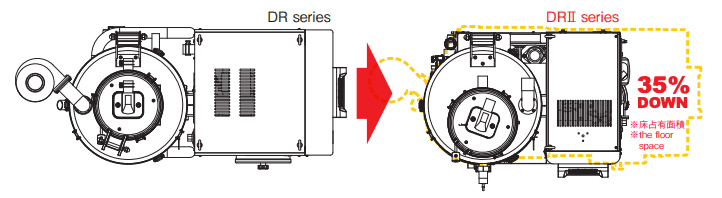

35% reduction in size compared to previous models

By integrating the dryer and loader, the floor space is reduced by 45%. Floor space is also reduced by 35% compared to conventional integrated machines.

Semi-closed method reduces power consumption by up to 38%.

By returning most of the hot air from the dryer to the heater, the power consumption is greatly reduced.

| Waste heat to the air (THD) | 1.5313 kwh |

| Semi-closed method (DRII-50F) | 0.9421 kwh |

| Power consumption | Approx. 38% reduction |

Stable molding quality

Removes excess powder of recycled material with helical hopper type.

The maximum temperature can be set up to 150°C to accommodate resins that require high temperature drying.

.jpg)

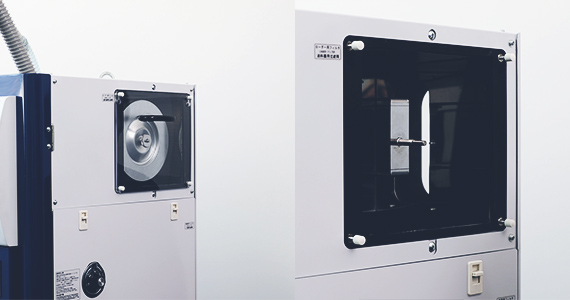

Helical Hopper Specifications; Improves defects by thorough dust removal.

- Resin material is separated into "powder" and "material" by the spiral airflow and agitation airflow generated in the hopper.

- This equipment thoroughly removes dust.

Structure and Principle

While rotating the resin material transported in a fixed quantity in the hopper, the fine powder contained in the resin material is collected from the air suction port at the top of the hopper to the collector side.

At this point, agitation air is sent from the bottom of the hopper, and the resin material is fed back into the hopper by the delivered air and the fine powder adhering to the surface of the resin material is repeatedly removed.

Features

- The hopper collects the dust in the material conveying line and keeps the occupying space to the minimum.

- The air swirls in the hopper to isolate and collect the pellet dust efficiently.

(The hopper is also usable for quick mixing of crushed materials.) - Upper filter shape and size are changed. Achieves the best dust collection.

Improve productivity by making maintenance easy

Maintenance (cleaning time, etc.) is reduced by 50% compared to conventional models

- No tools are required, and daily cleaning that occurs with material changes, etc., can be easily performed.

- The drum and lid parts can be opened to expose all the parts, making it easy to see at a glance where cleaning is needed.

- This contributes to shorter cleaning and setup times.

.png)

Other features that contribute to increased productivity

Material level gauge (standard)

The position of the material level gauge is adjustable to optimize.

In the case of small-volume production, the work of removing remaining material after the end of production is eliminated, which reduces setup and changeover.

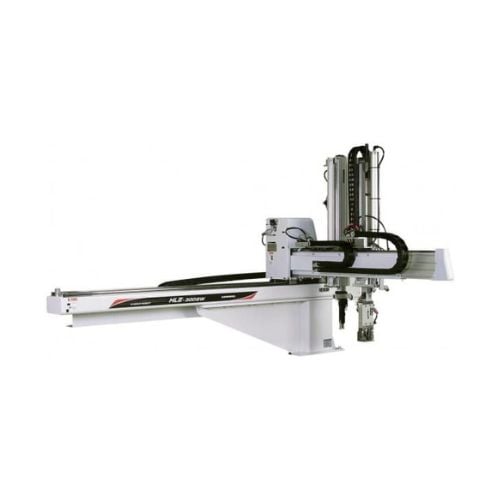

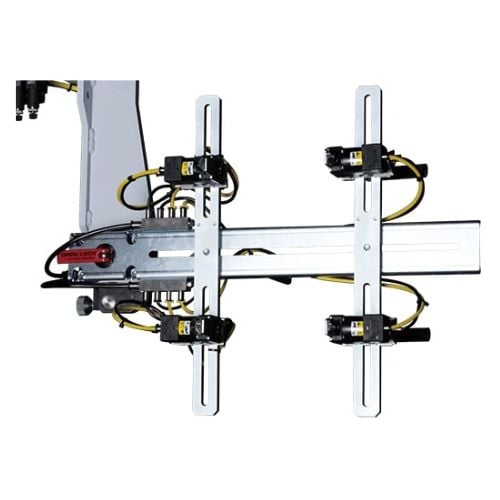

Batch management of settings, startup, and monitoring of peripheral equipment

HAL-NET(HARMO ALL-AROUND LINK-NET)

The HARMO Traverse (HRXⅢ Series) enables batch control of HARMO dryer & loader integrated units and other peripheral equipment.

- Once the settings are saved, all equipment can be linked by simply selecting the name of the mold to be molded in the traverse.

- Prevents mistakes such as incorrect temperature settings, and shortens setup time.

- Peripheral equipment placed outside the clean room can also be set using the take-out robot.

.jpg?width=849&height=300&name=%E5%91%A8%E8%BE%BA%E6%A9%9F%E5%99%A8%E9%80%9A%E4%BF%A1(HAL-NET).jpg)

Others

- THD-F / FH series

-

- Hopper Dryer

- Hot air type

- IMM size : 50 - 400ton

- Max. temperature 120°C

- THD-5α/THD-5Jα

-

- Ultra-Small Hopper Dryer / Dehumidifier

- Dehumidifying type (J type) is also available.

- MDRⅡ series

-

- Dehumidifyer Dryer

- Thorough dehumidifying drying improves defect rate

- Stabilization of moisture content

Product Specifications

(10~15kg), 25~42

(15~25kg), 42~83

(25~50kg), 42~125

(25~75kg)], product_name=Drying hopper (Material: SUS) Adjustment range *1 (ℓ)}, {product_item=[3.5/4.2, 3.5/4.2, 3.5/4.2, 3.5/4.2], product_name=Conveying blower Air volume (50/60Hz) (m3/min)}, {product_item=[15.0/20.0, 15.0/20.0, 15.0/20.0, 15.0/20.0], product_name=Conveying blower static air pressure (50/60Hz) (KPa)}, {product_item=[1.5/1.75, 1.5/1.75, 1.5/1.75, 1.5/1.75], product_name=Conveying blower electric motor output (kw)}, {product_item=[0.5 or more, 0.5 or more, 0.5 or more, 0.5 or more], product_name=Required compressed air pressure (MPa)}, {product_item=[Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber], product_name=Circulation side filter material}, {product_item=[Equivalent to 10, Equivalent to 10, Equivalent to 10, Equivalent to 10], product_name=Circulation filter filtration performance (μ)}, {product_item=[Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber, Cellulose fiber

Chemical fiber], product_name=Transport side filter material}, {product_item=[Equivalent to 10, Equivalent to 10, Equivalent to 10, Equivalent to 10], product_name=Circulation filter filtration performance (μ)}, {product_item=[Standard φ38

Helical φ38 /φ50, Standard φ38

Helical φ38 /φ50, Standard φ38

Helical φ38 /φ50, Standard φ38

Helical φ38 /φ50], product_name=Hose diameter Air suction pipe diameter (mm)}, {product_item=[φ38, φ38, φ38, φ38], product_name=Hose diameter Material suction pipe diameter (mm)}, {product_item=[6.0, 6.0, 6.0, 6.0], product_name=Conveying hopper on dryer side Effective capacity (ℓ)}, {product_item=[3-phase AC200

(50/60Hz), 3-phase AC200

(50/60Hz), 3-phase AC200

(50/60Hz), 3-phase AC200

(50/60Hz)], product_name=Power supply voltage (V)}, {product_item=[18, 17, 25, 25], product_name=Rated current (A)}, {product_item=[3.55/3.8, 4.55/4.8, 7.05/7.3, 7.2/7.45], product_name=Power consumption (kw)}, {product_item=[PID control, PID control, PID control, PID control], product_name=Temperature controller Control method}, {product_item=[ K(CA), K(CA), K(CA), K(CA)], product_name=Temperature controller Sensor input type}, {product_item=[G Hopper 50, G Hopper 50, G50 / G100, G Hopper 100], product_name=Conveying hopper ( standard specification ) on molding machine side Hopper type *2}, {product_item=[ 1.7, 1.7, 1.7 / 7, 7], product_name=Conveying hopper ( standard specification ) on molding machine side Capacity (ℓ)}, {product_item=[HG50

Helical Hopper, HG50

Helical Hopper, HG50 / HG100

Helical Hopper, HG100

Helical Hopper], product_name=Conveying hopper (Helical specification) on molding machine side Hopper type *2}, {product_item=[4.9, 4.9, 4.9 / 5.6, 5.6], product_name=Conveying hopper (Helical specification) on molding machine side Capacity (ℓ)}, {product_item=[165, 172, 186, 192], product_name=Weight (kg)}], rich_text=, rich_text_2=

※1. Varies depending on the supply air condition.

※2. The capacity(ℓ) is based on the 0.6 apparent specific gravity of the ABS virgin pellet.

※3. For 50K standard type, 50 or 100 G Hopper can be selected, and for helical hoppers, HG50 or HG100 can be selected.

, set={check=false, set1={set_title=対象成形機(ton)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set2={set_title=メイン上下ストローク(mm)}, set20={set_title=最大所要電流(A)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=DRⅡ Series}]DRⅡ Series

| DRⅡ-15F(-HG) | DRⅡ-25F(-HG) | DRⅡ-50F(-HG) | DRⅡ-75F(-HG) | |

|---|---|---|---|---|

| Type | Hot air type | Hot air type | Hot air type | Hot air type |

| Drying temperature (℃) | 80~150 | 80~150 | 80~150 | 80~150 |

| Drying blower air volume (50/60Hz) (m3/min) | 3.2/3.7 | 3.2/3.7 | 6.4/7.1 | 9.5/10.6 |

| Drying blower static air pressure (50/60Hz) (KPa) | 0.4/0.61 | 0.4/0.61 | 0.63/0.91 | 0.91/1.3 |

| Drying blower motor output (kw) | 3 phase 0.05 | 3 phase 0.05 | 3 phase 0.15 | 3 phase 0.3 |

| Drying heater (kw) | 2.0 | 3.0 | 5.4 | 5.4 |

| Drying hopper (material: SUS) maximum stocking capacity *1 (ℓ) | 25(15kg) | 42(25kg) | 83(50kg) | 125(75kg) |

| Drying hopper (Material: SUS) Adjustment range *1 (ℓ) |

17~25 (10~15kg) |

25~42 (15~25kg) |

42~83 (25~50kg) |

42~125 (25~75kg) |

| Conveying blower Air volume (50/60Hz) (m3/min) | 3.5/4.2 | 3.5/4.2 | 3.5/4.2 | 3.5/4.2 |

| Conveying blower static air pressure (50/60Hz) (KPa) | 15.0/20.0 | 15.0/20.0 | 15.0/20.0 | 15.0/20.0 |

| Conveying blower electric motor output (kw) | 1.5/1.75 | 1.5/1.75 | 1.5/1.75 | 1.5/1.75 |

| Required compressed air pressure (MPa) | 0.5 or more | 0.5 or more | 0.5 or more | 0.5 or more |

| Circulation side filter material |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

| Circulation filter filtration performance (μ) | Equivalent to 10 | Equivalent to 10 | Equivalent to 10 | Equivalent to 10 |

| Transport side filter material |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

Cellulose fiber Chemical fiber |

| Circulation filter filtration performance (μ) | Equivalent to 10 | Equivalent to 10 | Equivalent to 10 | Equivalent to 10 |

| Hose diameter Air suction pipe diameter (mm) |

Standard φ38 Helical φ38 /φ50 |

Standard φ38 Helical φ38 /φ50 |

Standard φ38 Helical φ38 /φ50 |

Standard φ38 Helical φ38 /φ50 |

| Hose diameter Material suction pipe diameter (mm) | φ38 | φ38 | φ38 | φ38 |

| Conveying hopper on dryer side Effective capacity (ℓ) | 6.0 | 6.0 | 6.0 | 6.0 |

| Power supply voltage (V) |

3-phase AC200 (50/60Hz) |

3-phase AC200 (50/60Hz) |

3-phase AC200 (50/60Hz) |

3-phase AC200 (50/60Hz) |

| Rated current (A) | 18 | 17 | 25 | 25 |

| Power consumption (kw) | 3.55/3.8 | 4.55/4.8 | 7.05/7.3 | 7.2/7.45 |

| Temperature controller Control method | PID control | PID control | PID control | PID control |

| Temperature controller Sensor input type | K(CA) | K(CA) | K(CA) | K(CA) |

| Conveying hopper ( standard specification ) on molding machine side Hopper type *2 | G Hopper 50 | G Hopper 50 | G50 / G100 | G Hopper 100 |

| Conveying hopper ( standard specification ) on molding machine side Capacity (ℓ) | 1.7 | 1.7 | 1.7 / 7 | 7 |

| Conveying hopper (Helical specification) on molding machine side Hopper type *2 |

HG50 Helical Hopper |

HG50 Helical Hopper |

HG50 / HG100 Helical Hopper |

HG100 Helical Hopper |

| Conveying hopper (Helical specification) on molding machine side Capacity (ℓ) | 4.9 | 4.9 | 4.9 / 5.6 | 5.6 |

| Weight (kg) | 165 | 172 | 186 | 192 |

| DRⅡ-15F(-HG) | DRⅡ-25F(-HG) | DRⅡ-50F(-HG) | DRⅡ-75F(-HG) |

※1. Varies depending on the supply air condition.

※2. The capacity(ℓ) is based on the 0.6 apparent specific gravity of the ABS virgin pellet.

※3. For 50K standard type, 50 or 100 G Hopper can be selected, and for helical hoppers, HG50 or HG100 can be selected.

Others

- THD-F / FH series

-

- Hopper Dryer

- Hot air type

- IMM size : 50 - 400ton

- Max. temperature 120°C

- THD-5α/THD-5Jα

-

- Ultra-Small Hopper Dryer / Dehumidifier

- Dehumidifying type (J type) is also available.

- MDRⅡ series

-

- Dehumidifyer Dryer

- Thorough dehumidifying drying improves defect rate

- Stabilization of moisture content

New Information about this product

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

About us

Company name

HARMO Co., Ltd.

Business Activities

Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts) and streamlined auxiliary machines for plastic molding machine

Address

4124-1 Minamiminowa-mura Kamiina-gun Nagano, Japan 399-4595

Phone

+81-265-73-8820

International Marketing Department

- Address 4124-1 Minamiminowa-mura Kamiina-gun Nagano, 399-4595

- TEL : 0265-73-8820

- FAX : 0265-73-8964

- E-mail : kaigai@harmo-net.co.jp

- Sales Office (Subsidiary) Singapore, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America

- Factory Suzhou

Sales Office (Subsidiary)

SINGAPORE

HARMO CO.,(SINGAPORE) PTE., LTD.

23TAGORE LANE #01-03 TAGORE 23 WAREHOUSE

SINGAPORE 787601

- TEL : +65-6481-1764

- FAX : +65-6481-6130

- E-mail : general@harmo.com.sg

INDONESIA

Festival Boulevard Blok AA 11 No61 Grand Wisata Desa Lambangsari Kec. Tambun-Selatan Kab. Bekasi 17510

- TEL : 021-8262-1667 / 68

- FAX : 021-8262-1726

- E-mail : hiro-tsuchiya@harmo-net.co.jp

MALAYSIA

HARMO CO., (MALAYSIA) SDN. BHD.

LOT 0034, KOMPLEKS SENTRAL No.33, JALAN SEGAMBUT

ATAS 51200 KUALA LUMPUR MALAYSIA

- TEL : +60-3-6251-2057

- E-mail : t_osaki@harmo-net.co.jp

Penang Office

HARMO CO., (MALAYSIA) SDN. BHD.

No.10, GROUND FLOOR JALAN PERAI JAYA 6, BANDAR BARU

PERAI JAYA, 13700 PERAI PENANG MALASIA

- TEL : +60-4-3972057

- E-mail : t_osaki@harmo-net.co.jp

THAILAND

HARMO (THAILAND) LTD.

410/71-72 SOI RATCHADAPISEK 24,RATCHADAPISEK RD., SAMSENNORK,HUAY-KWANG, BANGKOK 10310

- TEL : +66-2-541-4287

- FAX : +66-2-541-4286

- E-mail : t_nakazawa@harmo-net.co.jp

SHENZHEN

HARMO MACHINERY (SHENZHEN) CO., LTD.

Room 8213, JinBao business building, 15 Shun Feng Road, 44 District,AnLe Community, Xin’an street, Baoan District, Shenzhen. China

- TEL : (+86) 755-88868177

- FAX : (+86) 755-83862500

- E-mail : szoffice@harmo-net.com

SHANGHAI

HARMO MACHINERY (SHANGHAI) CO., LTD.

Room 805, North Tower,Guanghua Building, 870 Maotai Road, Changning District,Shanghai

- TEL : +86-21-80199227

- FAX : +86-21-80199228

- E-mail : harmosh@harmo-net.com

Dalian Office

Room 1005, Gugeng International Hotel, No.138, Jinma Road, Dalian P.R. China 116600

- TEL : (0411)87962819

- FAX : (0411)87962819

Tianjin Office

Room 323,Yunhan Building,No.185,Qinjian Road,Hongqiao District,Tianjin 300130

- TEL : (022)87355626

- FAX : (022)87355626

Xiamen Office

Room B415, Xinxinjingdi Building, No.396, Jiahe Road, Huli District, Xiamen

- TEL : 0592-3233250

- FAX : 0592-3233250

HOCHIMINH Office

Harmo America inc.

2675 American Lane Elk Grove Village IL 60007

- TEL : +1-630-594-4116

- URL : www.harmo-america.com

SUZHOU

HARMO (SUZHOU) CO., LTD.

NO.15 XIANGPU ROAD, SHENGPU TOWN, SUZHOU INDUSTRIAL PARK, SUZHOU

- TEL : (+86) 512-6295-5112

- FAX : (+86) 512-6295-5117

- URL : www.harmo.com.cn/

Global agency

Korea

HANSE KOREA Co., Ltd.

#503,DAERUNG TECHNOTOWN 7CHA,489-11 GASAN-DONG,GEUMCI-KU,SEOUL,KOREA

- TEL: +82-2-2108-4511〜9

- FAX: +82-2-2108-4510

- URL: http://han-se.com

Philippines

NPI Machinery Inc

5th Floor Orcel II Bldg. 1611 Quezon Avenue, West Triangle, Quezon City, 1100 Philippines

- TEL: (632)926-7479

- FAX: (632)920-3096

Taiwan

XIN JU AUTOMACHINE CORP.

NO.25,Changchun 6th Rd., Zhongli Dist., Taoyuan City 320, Taiwan(R.O.C)

- TEL:886-3-4623797

- FAX:886-3-4622397

Australia

Cam-Plas Machinery Pty. Ltd.

2/30 Catherine Street, Coburg North, VICTORIA, Australia, 3058

- TEL: +61-3-9355-7099

New Zealand

TCL Hunt Limited.

7 Fisher Crescent Mount Wellington Auckland 1060 PO Box 132-166 Sylvia Park Auckland 1644 New Zealand

- TEL: +64-9-526-2700

- FAX: +64-9-525-0875

- URL: https://tclhunt.co.nz/

Brazil

Hercx Representação de Máquinas e Equipamentos Plásticos Ltda

Alameda Princesa Isabel, 654 – São Bernardo do Campo – São Paulo, CEP 09771-110, Brazil

- TEL: +55 11 2677-3040

- MOBILE: +55 11 99898-6066

- E-mail: hercules@hercx.net

Mexico

Otakara PLASTICOS

Jeronimo Trevino 3835 Col. Lopez Portillo Guadalajara, Jalisco, Mexico C.P. 44980

- TEL: +52-(33)-3663-9798

- FAX: +52-(33)-3646-2364

- URL: http://www.otakaraplasticos.com/

Israel

Multipack

3, Derech Hyam St. P.O. Box 376 81103 Yavne Israel

- TEL: +972-8942-7325

- FAX: +972-8942-0397

Italy

STAGE TECHNOLOGIES

ST.A.TE Technologies Srl Vail Vailate 15 / A、24040-Calvenzano(BG)

- TEL: 0363 8535209

- FAX: 0363 853115

- URL: http://www.state-tech.it/

Poland

HARMO REPRESENTATIVE POLAND & EAST EUROPE

ul. Kazimierza Pułaskiego 2 64-600 Oborniki

- TEL: +48-608-489-327

- E-mail: ds@darsta.pl

- URL: https://www.darsta.pl/

INDIA

KANEHIRO YANTRA PRIVATE LIMITED

Flat No 22, krishna Apartment, No.59, 1st Avenue, Ashok Nagar, Chennai – 600 083, Tamil Nadu, India.

- TEL: +91 (44) 4856-7520

- MOBILE: +91 (98) 8405-7520

- E-mail: keshavan@kanehiro.co.in

- URL: https://www.kanehiro.co.in/

.jpg?width=500&height=500&name=%E8%B6%85%E5%A4%A7%E5%9E%8B%E4%BB%95%E6%A7%98%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%20(1).jpg)

%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg?width=500&height=500&name=_%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC(%E4%BD%9C%E8%A3%BD%E4%BE%8B)%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg)

.jpg?width=500&height=500&name=%E5%90%B8%E7%9D%80%E3%83%91%E3%83%83%E3%83%88%E3%81%AE%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=%E3%83%AF%E3%83%B3%E3%82%BF%E3%83%83%E3%83%81%E3%82%A2%E3%82%BF%E3%83%83%E3%83%81%E3%83%A1%E3%83%B3%E3%83%88%7C%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC%20(%E5%8F%96%E5%87%BA%E6%A9%9F%E5%81%B4)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=HC15BPX%7C%E3%83%AC%E3%83%90%E3%83%BC%E3%83%81%E3%83%A3%E3%83%83%E3%82%AF(%E3%83%95%E3%82%A3%E3%83%B3%E3%82%AC%E3%83%BC%E3%83%84%E3%83%BC%E3%83%AB%E4%BB%98)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)