Contributes to lower manufacturing costs by improving resin recycling rate

HARMO's "Gran Cutter"

- Processing Capacity 30~40g / min

- Sprue Diameter Less than φ 6mm

- Cartridge

- Eco (Inverter)

- Hard type

- Processing Capacity 30~40g / min

- Sprue Diameter Less than φ 6mm

- Cartridge

- Eco (Inverter)

- Soft type

- Processing Capacity 90~120g / min

- Sprue Diameter Less than φ 8mm

- Cartridge

- Eco (Inverter)

- Hard type

- Processing Capacity 90~120g / min

- Sprue Diameter Less than φ 8mm

- Cartridge

- Eco (Inverter)

- Soft type

- Processing Capacity 150~200g / min

- Sprue Diameter Less than φ 8mm

- Hard type

- CE

.jpg)

- Processing Capacity 150~200g / min

- Sprue Diameter Less than φ 8mm

- Soft type

- CE

.jpg)

- Processing Capacity 150~200g / min

- Sprue Diameter Less than φ 8mm

- Hard type

- CE

.jpg)

- Processing Capacity 150~200g / min

- Sprue Diameter Less than φ 8mm

- Soft type

- CE

.jpg)

- Processing Capacity 547~684g / min

- Sprue Diameter Less than φ 13mm

- Hard type

- Processing Capacity 523~654g / min

- Sprue Diameter Less than φ 13mm

- Soft type

New functions of renewal model of "SPCⅢSeries"

- Processing Capacity 320~400g / min

- Sprue Diameter Less than φ 13mm

- Hard type

- Processing Capacity 320~400g / min

- Sprue Diameter Less than φ 13mm

- Soft type

.jpg)

- Processing Capacity 320~400g / min

- Sprue Diameter Less than φ 13mm

- Hard type

- CE

.jpg)

- Processing Capacity 320~400g / min

- Sprue Diameter Less than φ 13mm

- Soft type

- CE

Energy-saving operation contributes to cost savings in electricity bills

- Gran-Cutter cuts runners with very little dust. No more wasting the materials

- The equipped inverter controls the motor output to the optimum level; 28% energy saving

- Automatic idling saves about 60% electric power.

(The machine detects the runners and automatically starts normal operation.) *Please refer to notes.

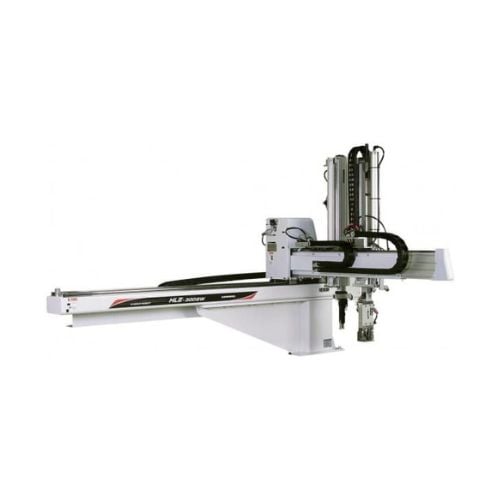

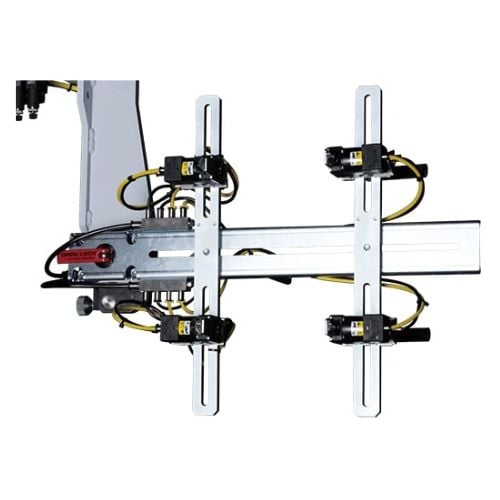

Mountable on SPC Ⅱ and GM Ⅱ units

- SPCII-200e/400e/750e、SPCII-200Se/400Se/750Se

- GMII-200e/400e/750e、GMII-400Se/750Se

※Specifications and dimensional drawings are based on standard Gran Cutter and Gran Mixer.

Notes

* Because the small or the soft runners have little effect on the load fluctuation, Gran-Cutter may not detect the runners and restart the normal operations from idling. The idling on/off switch is available on Gran-Cutter for such case. Use the switch accordingly with the runners. (The waiting time to switch to idling is fixed at 60 seconds.)

HARMO's "Gran Cutter" improves the recycling rate of recycled materials.

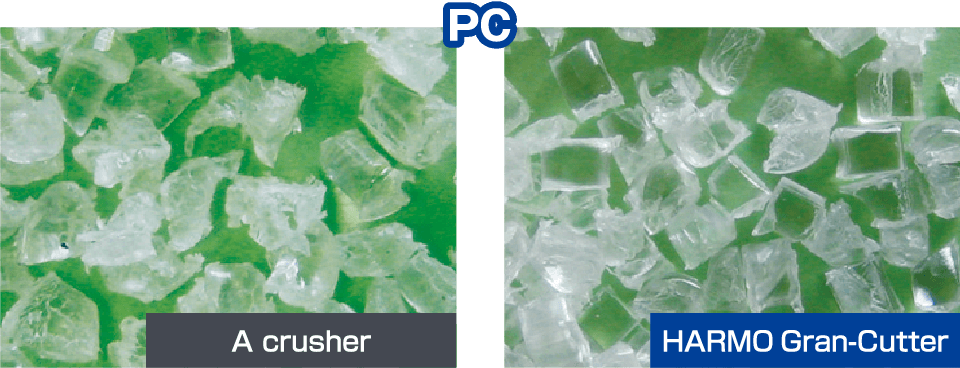

HARMO's "Gran Cutter" is totally different from conventional crushers.

It eliminates the cause of powder generation in injection molding and minimizes heat and static electricity generation.

Sprue and runners can be cut into neat granular shapes that are close to those of virgin materials, leading to improved recycling rates in injection molding, which has been well accepted by many users.

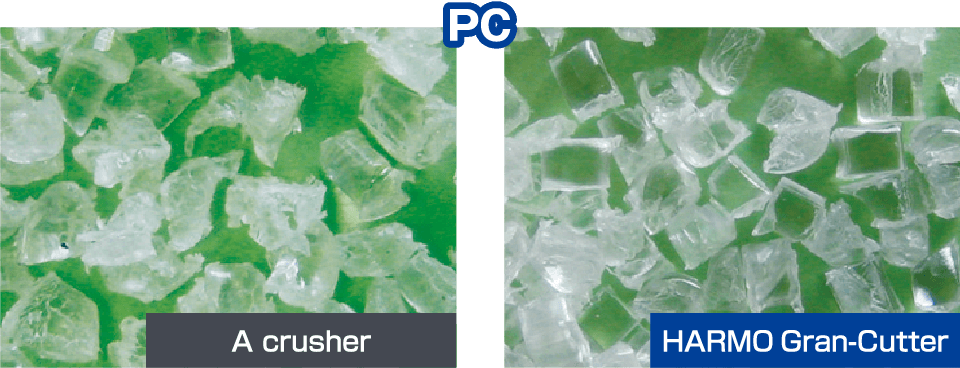

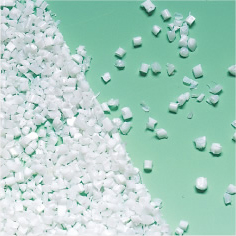

Features of recycled sprues and runners cut by "Gran Cutter"

- Low powder content and uniform grain (closer to that of virgin material)

- Reduced weight time, stable molding, and less burns.

- The mixing ratio of recycled materials can be more than doubled.

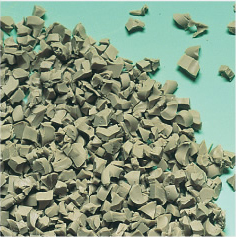

- Recycled soft materials such as elastomers can be properly recycled with a dedicated machine.

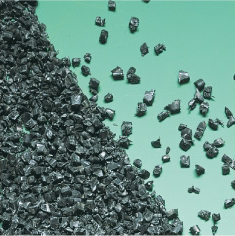

A certain company's grains are uneven with cracks due to impact, while HARMO maintains transparency and the grains are uniform.

.png)

HARMO cuts 90% of the grains at the targeted size (2.8m/m to 4m/m), and the grain size is consistent.

Example of hard material cut by "Gran Cutter" (recycled material)

Example of soft material cut by "Gran Cutter" (recycled material)

Realization of recycled material that is almost the same size as virgin material

.jpg)

The above graph shows an objective comparison of our Gran Cutter with those of three other manufacturers by a customer who has purchased many of HARMO's Gran Cutters and has molded recycled materials.

It is obvious that our Gran Cutter is much superior, especially in terms of stability of weighing time.

HARMO's grains have less variation in size, and the weighing time is shorter because there is less powder, and the weighing time has less variation.

Summary of "Gran Cutter" features

- Very little powder is generated.

Since the blade does not pass through the cut area once it has been cut, the generation of powder, static electricity, and heat can be suppressed.

- Surprisingly few miscuts. Grain can be cut closer to virgin material.

The material comes to a specified size at the time of being cut. The mechanism allows grains to be cut to a size closer to that of virgin material.Almost no miscuts and no screen

Recycling rate 0% → 10%

Molded products of recycled materials for camera lenses

- User

A camera manufacturer

- Injection molding resin material

Optical material

- The company had been molding lenses using high-grade resin (3,000 yen/kg), but realized a significant reduction in production costs by increasing the recycling rate.

Annual cost reduction of 200 million yen

Molding of recycled materials for automobile parts

- User

An automobile parts manufacturer

- Material

Multiple types

- The recycling rate has increased with the introduction of HARMO's Gran Cutter. Succeeded in reducing production costs by 200 million yen per year.

Bridge problem (clogging) solved

Smooth and stable operation

- User

A certain groceries manufacturer

- Material

ABS resin

- The conventional crusher had many miscuts, and bridging occurred in the hopper section five times a day. the Gran Cutter's agitating motor secured fluidity to prevent bridging and realized stable production without bridging.

Achieved 20% recycled mixture ratio

Improved quality of recycled materials

- User

An eyeglass parts manufacturer

- Injection molding resin material

Optical material

- The company had been molding lenses using high-grade resin (3,000 yen/kg), but realized a significant reduction in production costs by increasing the recycling rate.

- I am troubled by fluffiness of crushed grains|PE (polyethylene)

Question.

We produce automobile parts using PE. We recycle resin using a crusher, but the crushed particles become fluffy and clog up the material tank or bridge in the hopper of the molding machine, which prevents continuous molding and prevents us from increasing productivity. Is there any good solution?

Answer

After test cutting with the Gran Cutter, the PE material grains no longer fluff up. When continuous molding was carried out using a rental demo unit, the problems of resin conveyance and bridging in the molding machine hopper were resolved, and 24-hour continuous molding became possible, which led Gran Cutter to be introduced.

- We are troubled by the appearance quality abnormality of products due to discoloration of products when PBT is reused. |PBT (Polybutylene terephthalate)

Question.

When we tried to reuse white PBT natural material after crushing it with a high-speed crusher, it turned gray and the appearance quality of the product became abnormal. We have tried testing with a low-speed crusher, but the situation stays the same, and we are unable to achieve cost reduction through material recycling. Is there a better solution?

Answer

When we cut a sample with Gran Cutter, no discoloration of the resin was observed, and we were able to realize cost reduction by material recycling with the introduction of Gran Cutter.

- It is difficult to recycle resin that maintains optical characteristics. |MIM (Metal Injection Molding)

Question

We make lenses for optical equipment by molding with COP. Since the material is expensive, we would like to consider cost reduction through recycling. We tested the material using a general crusher, but there was a large variation in the MI value (resin flowability value), and we were unable to obtain the optical characteristics of the lenses. Since the resin is transparent, we are also concerned about discoloration caused by the recycled material. Is there a better way?

Answer

After test cutting with the Gran Cutter, the PE material grains no longer fluff up. When continuous molding was carried out using a rental demo unit, the problems of resin conveyance and bridging in the molding machine hopper were resolved, and 24-hour continuous molding became possible, which led Gran Cutter to be introduced.

- We have trouble with soft PVC recycled material|COP (Cyclo-olefin polymer)

Question

We mold medical equipment using PVC, which is soft and cannot be cut well with an ordinary crusher, causing bridging in the hopper and preventing continuous molding using recycled material. Is it possible to cut the soft resin uniformly?

Answer

We have done a test cut with Gran Cutter, which is dedicated for soft materials, and found that it could crush the material into uniform granules, and obtained good results in the continuous molding test. As a result, we were able to realize cost reduction by introducing the Gran Cutter. In addition, from the perspective of Co2 reduction, we were able to achieve a Scope 3 Co2 reduction effect by reducing waste resin.

- We are concerned about whether the strength of our products can be maintained,because the fiber length of the glass-reinforced material is shortened by crushing|PVC (polyvinyl chloride/polyvinyl chloride)

Question

We use 30% PA glass as a substitute for metal automobile parts. We are considering using recycled materials to reduce costs, but we are concerned about whether we can maintain the strength of our products, because the fibers of the glass reinforcement material become shorter due to crushing. Is there a better way to do this?

Answer

We conducted a comparative analysis of samples cut with Gran Cutter and those cut with other companies' crusher, and found that the Gran Cutter can cut the glass fiber length without loss of fiber length. In the recycling of resin materials which contain reinforced materials such as glass fiber, the performance of the Gran Cutter was found to be superior to that of other companies' crushers.

- We are troubled by carbonized black spot defects that impede our ability to maintain the insulation quality of our electronic components. | PA (polyamide)

Question

We mold electronic components with 40% PPS glass resin. We use a high-speed crusher to crush the sprue runner and to reduce the material, but there is a lot of powder, and we cannot maintain the insulation quality of electronic components due to carbonized black point defects, which requires a lot of manpower to sort out product defects, making it impossible to increase productivity. In addition, when the material is crushed with a high-speed crusher, the screen wears out in the form of long holes, resulting in long sprue runners that bridge on the hopper of the molding machine, making continuous molding impossible. Moreover, because the material contains 40% glass, the crusher blades are subject to heavy wear and frequent sharpening, resulting in high running costs. Is there any good solution to this problem?

Answer

Test cutting with Gran Cutter showed that almost no fine powder, which is considered to be the cause of black spots, was generated, and although some fine grains were observed, there was no influence on product quality, and black spot defects caused by powder were drastically reduced. In addition, bridging of resin in the molding machine hopper due to miscuts has been eliminated, enabling 24-hour continuous molding and higher productivity. Furthermore, the use of a high-speed steel optional blade has reduced running costs compared to the conventional method.

- We are having trouble in recycling high-viscosity and high-hardness resin|PPS (Polyphenylene Sulfide)

Question

We use PEEK, a super engineering plastic, to mold aircraft parts. We are considering recycling the resin because it is expensive. The sprue runners tend to be thicker than those of general-purpose resins because of the high viscosity and hardness of the resin, and normal crushers have problems of chipped blades and are unable to crush the sprue runners evenly, making it difficult to recycle them properly. Is there any good way to do this?

Answer

Test cutting with Gran Cutter yielded recyclable grains under certain conditions. As for blade wear, we found that wear was faster than that of normal resin. When we compared the maintenance costs of Gran Cutter with the benefits of resin reduction through recycling, the benefits outweighed the costs, so we decided to introduce Gran Cutter. In addition, since there was a concern of blade chipping, a metal removal system was additionally installed to prevent metal from being supplied to the screw cylinder.

Do you have any of these problems with recycling sprues and runners for injection molding?

- Inconsistent molding quality with recycled materials.

- Want to reduce production costs by increasing the recycling rate of recycled materials.

- Heavy amounts of dust are generated during the crushing of recycled materials, and it takes time to clean up and set up.

- The factory environment is noisy and uncomfortable.

- Want to convert injection molding to recycled pellets.

HARMO's "Gran Cutter" can solve these problems.

It contributes to improving the recycling rate of recycled materials and reducing the cost of materials.

HARMO's "Gran Cutter" is totally different from conventional crushers. It eliminates the cause of powder generation in injection molding and minimizes heat and static electricity generation.

Sprue and runners can be cut into neat granular shapes that are close to those of virgin materials, leading to improved recycling rates in injection molding, which has been well accepted by many users.

Please try the free rental & sample cutting of the demo unit.

Please try a test cut of resin.

You can try a test cut of the plastics used in your company. Our staff will attend the test cut to explain about the equipment, making suggestions for improvement in plastic recycling.

Sample cutting is also available.

We can also offer sample cutting by receiving runners and other materials from your company. In this case, please prepare about 30 shots of runner.

Please see the downloadable documents.

We recommend this for these people.

- It takes a lot of time and effort to adjust the recycled material.

(injection molding machine operators) - It is hard to make a production plan.

( production line supervisor ) - Molding defects occur when the percentage of recycled material is increased.

(Quality controller) - Having a hard time in competing for resins.

( Factory manager ) - The soaring cost of raw materials is giving me a headache.

( Managers )

Product specifications

(37.5rpm/50Hz ・45rpm/60Hz), 98mm diam, 4pcs

(37.5rpm/50Hz ・45rpm/60Hz)], product_name=Rotating cutter}, {product_item=[2.1mm × 3.5mm 24pcs

・75cycles/min (50Hz)

・90cycles/min (60Hz)

,

2.1mm × 3.5mm 24pcs

・75cycles/min (50Hz)

・90cycles/min (60Hz)

Option Magnetic Bar、Hopper with Anti-Scatter Shutter、Safety Hopper (Z type)、Safety Hopper (Z type)、Signal Tower、Auxiliary Chute、Buzzer、Paper Bag Frame、Suction Tank、Emergency stop button

, rich_text_2=*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

, set={set20={set_title=最大所要電流(A)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, check=false, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set1={set_title=対象成形機(ton)}, set2={set_title=メイン上下ストローク(mm)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=SPCⅡ-C200/SPCⅡ-C200S}, {item=[SPCⅡ-C400, SPCⅡ-C400S], pdf_group=[{pdf=https://8087610.fs1.hubspotusercontent-na1.net/hubfs/8087610/catalog/sogo08-G9G10.pdf, pdf_text=View product catalog}], product=[{product_item=[Indoor, Indoor], product_name=Place of operation}, {product_item=[-10~+40, -10~+40], product_name=Ambient temperature(℃)}, {product_item=[~85, ~85], product_name=Ambient humidity(%)}, {product_item=[3-phase AC200(50Hz/60Hz), 3-phase AC200(50Hz/60Hz)], product_name=Power input(V)}, {product_item=[430, 430], product_name=Power equipment capacity(VA)}, {product_item=[2.15, 2.15], product_name=Current consumption(A)}, {product_item=[Geared motor 0.2KW-3P, grounded, Geared motor 0.2KW-3P, grounded], product_name=Motor}, {product_item=[98mm diam, 4pcs

(37.5rpm/50Hz ・45rpm/60Hz)

(37.5rpm/50Hz ・45rpm/60Hz)], product_name=Rotating cutter}, {product_item=[

2.1mm × 3.5mm 24pcs

・75cycles/min (50Hz)

・90cycles/min (60Hz)

・75cycles/min (50Hz)

・90cycles/min (60Hz)], product_name=Press moving cutter }, {product_item=[162 × 162, 162 × 162], product_name=Mouth on main body(mm)}, {product_item=[200 × 162, 200 × 162], product_name=Hopper throat(mm)}, {product_item=[-, -], product_name=Material tank volume(ℓ)}, {product_item=[φ 6mm or smaller, φ 6mm or smaller], product_name=Cuttable sprue diameter(mm)}, {product_item=[Intermittent feeding, 30 through 40g max. per minute, Intermittent feeding, 30 through 40g max. per minute], product_name=Processing capacity}, {product_item=[95, 100], product_name=Machine weight(kg)}], rich_text=Option Magnetic Bar、Hopper with Anti-Scatter Shutter、Safety Hopper (Z type)、Safety Hopper (Z type)、Signal Tower、Auxiliary Chute、Buzzer、Paper Bag Frame、Suction Tank、Emergency stop button, rich_text_2=

*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

, set={set20={set_title=最大所要電流(A)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, check=false, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set1={set_title=対象成形機(ton)}, set2={set_title=メイン上下ストローク(mm)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=SPCⅡ-C400/SPCⅡ-C400S}, {item=[SPCⅢ-C750, SPCⅢ-C750S], pdf_group=[{pdf=https://8087610.fs1.hubspotusercontent-na1.net/hubfs/8087610/catalog/SPC3_leaf_ENG.pdf, pdf_text=View product catalog}], product=[{product_item=[3-phase AC200(50Hz/60Hz), 3-phase AC200(50Hz/60Hz)], product_name=Power input(V)}, {product_item=[0.75kw‐4P, 0.75kw‐4P], product_name=Motor}, {product_item=[3.2A/3.0A, 3.2A/3.0A], product_name=Rated current(A)}, {product_item=[φ176mm,4pcs

(37.5rpm/50Hz ・45rpm/60Hz)

(37.5rpm/50Hz ・45rpm/60Hz)], product_name=Rotating blade}, {product_item=[

2.8mm × 4.5mm 35pcs

150cycles/min (50Hz)・180cycles/min (60Hz)

150cycles/min (50Hz)・180cycles/min (60Hz)], product_name=Press moving cutter}, {product_item=[211 × 330, 211 × 330], product_name=Mouth on main body(mm)}, {product_item=[285 × 332, 285 × 332], product_name=Hopper throat(mm)}, {product_item=[6ℓ, 6ℓ], product_name=Material tank volume}, {product_item=[φ 8mm or smaller, φ 8mm or smaller], product_name=Cuttable sprue diameter(mm)}, {product_item=[150~200g, 150~200g], product_name=Intermittent feeding, 30 through 40g max. per minute}, {product_item=[168, 173], product_name=Machine weight(kg)}], rich_text=

TOTAL LINK (optional)

Connect with Total Link to monitor Gran Cutter's operation and shutdown.It also helps to improve productivity by detecting bridged of sprue and runner.

, rich_text_2=* The weight of material stored in the bin varies depending on the material type

* The hard type Gran cutter's processing capacity is the measured value when cutting the sprue; 6-nylon with 20% glass fiber, max. 6 mm diameter and 4g-weight

* The soft type Gran cutter's processing capacity is the measured value when cutting the sprue; thermoplastic elastomer, max. 6 mm diameter and 3g-weight

, set={set20={set_title=最大所要電流(A)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, check=false, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set1={set_title=対象成形機(ton)}, set2={set_title=メイン上下ストローク(mm)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=SPCⅢ-C750/SPCⅢ-C750S}, {item=[SPCⅢ-1500/SPCⅢ-1500S, Option], pdf_group=[{pdf=https://8087610.fs1.hubspotusercontent-na1.net/hubfs/8087610/catalog/SPC3-1500_JE.pdf, pdf_text=View product catalog}], product=[{product_item=[3-phase AC200(50Hz/60Hz), null], product_name=Power input(V)}, {product_item=[0.75kw‐4P, null], product_name=Motor}, {product_item=[6.4A / 6.0A, null], product_name=Rated current(A)}, {product_item=[φ220mm 4 pcs, 20mm thick

, null], product_name=Rotating blade}, {product_item=[Standard size blade : 3.8mm x 6mm, 42 pcs

, Optional small size blade : 2.8mm×4.5mm, 56pcs], product_name=Press moving cutter}, {product_item=[337mm (length) x 330mm (width), ], product_name=Mouth on main body(mm)}, {product_item=[374mm (length) x 332mm (width), ], product_name=Hopper throat(mm)}, {product_item=[Standard size blade 13mm or less, Optional small size blade 8mm or less], product_name=Cuttable sprue diameter(mm)}, {product_item=[Standard size blade (hard type): 547-684g/minStandard size blade (soft type): 523-654g/min, Optional small size blade (hard type): 320-400g/min

Optional small size blade (soft type): 302-378g/min], product_name=Processing capacity ※}, {product_item=[Two directions (motor side, side plate side), null], product_name=Hopper direction selection}, {product_item=[9ℓ, ], product_name=Material tank volume}, {product_item=[Max. 69.7dB (A) (before loading), null], product_name=Operating noise}, {product_item=[289kg | 285kg for the optional small size blade (hard type), ], product_name=Machine weight(kg)}], rich_text=, rich_text_2=

※ The model for hard material: The figures are calculated based on sprues of nylon 6 resin with 20% glass fiber, max. 6 mm in dia., 2.9 g in weight, 48 mm in width, and 94 mm in length.

※The model for soft material: The figures are calculated based on sprues of elastomer with max. 6.6 mm in dia., 2.4 g in weight, 22 mm in width, and 88 mm in length.

, set={set20={set_title=最大所要電流(A)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, check=false, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set1={set_title=対象成形機(ton)}, set2={set_title=メイン上下ストローク(mm)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=SPCⅢ-1500/SPCⅢ-1500S}, {item=[SPCⅡ-1500, SPCⅡ-1500S], pdf_group=[{pdf=https://8087610.fs1.hubspotusercontent-na1.net/hubfs/8087610/catalog/SPC3_leaf_ENG.pdf, pdf_text=View product catalog}], product=[{product_item=[Indoor, Indoor], product_name=Place of operation}, {product_item=[-10~+40, -10~+40], product_name=Ambient temperature(℃)}, {product_item=[~85, ~85], product_name=Ambient humidity(%)}, {product_item=[3-phase AC200(50Hz/60Hz), 3-phase AC200(50Hz/60Hz)], product_name=Power input(V)}, {product_item=[1330, 1330], product_name=Power equipment capacity(VA)}, {product_item=[6.15, 6.15], product_name=Current consumption(A)}, {product_item=[Geared motor 0.2KW-3P, grounded, Geared motor 0.2KW-3P, grounded], product_name=Motor}, {product_item=[φ220mm diam, 4pcs

(37.5rpm/50Hz ・45rpm/60Hz)

φ220mm diam, 4pcs

(37.5rpm/50Hz ・45rpm/60Hz)

3.8mm × 6mm 45pcs

・112.5cycles/min (50Hz)

・135cycles/min (60Hz)

・112.5cycles/min (50Hz)

・135cycles/min (60Hz)], product_name=Press moving cutter}, {product_item=[360 × 360, 360 × 360], product_name=Mouth on main body(mm)}, {product_item=[402 × 360, 402 × 360], product_name=Hopper throat(mm)}, {product_item=[9(4kg), 9(4kg)], product_name=Material tank volume(ℓ)}, {product_item=[φ 13mm or smaller, φ 13mm or smaller], product_name=Cuttable sprue diameter(mm)}, {product_item=[

Intermittent feeding, 320 through 400g max. per minute

, Intermittent feeding, 320 through 400g max. per minute], product_name=Processing capacity}, {product_item=[295, 295], product_name=Machine weight(kg)}], rich_text=Standard : Cleaning awl, Suction material tank for level gauge, Machine stops when level gauge material is full

Options: Press blade 6m/m, Material tank

, rich_text_2=*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

, set={set20={set_title=最大所要電流(A)}, set10={set_title=姿勢制御(°)}, set11={set_title=姿勢トルク(Nm)}, set12={set_title=姿勢トルク(Nm)}, set13={set_title=本体質量(kg)}, set14={set_title=横幅×奥行×全高(mm)}, set15={set_title=常用空気圧(MPa)}, set16={set_title=エア消費量 ※(ℓ/cyc[ANR])}, check=false, set17={set_title=制御方式}, set18={set_title=最大消費電力(W)}, set19={set_title=電源設備容量(VA)}, set1={set_title=対象成形機(ton)}, set2={set_title=メイン上下ストローク(mm)}, set3={set_title=サブ上下ストローク(mm)}, set4={set_title=メイン前後ストローク(mm)}, set5={set_title=サブ前後ストローク(mm)}, set6={set_title=横走行ストローク(mm)}, set7={set_title=メイン待機位置(mm)}, set8={set_title=メイン最大前進位置(mm)}, set9={set_title=サブ最小寄せ付け位置(mm)}}, sub_title=SPCⅡ-1500/SPCⅡ-1500S}]SPCⅡ-C200/SPCⅡ-C200S

Option Magnetic Bar、Hopper with Anti-Scatter Shutter、Safety Hopper (Z type)、Safety Hopper (Z type)、Signal Tower、Auxiliary Chute、Buzzer、Paper Bag Frame、Suction Tank、Emergency stop button

| SPCⅡ-C200 | SPCⅡ-C200 | |

|---|---|---|

| Place of operation | Indoor | Indoor |

| Ambient temperature(℃) | -10~+40 | -10~+40 |

| Ambient humidity(%) | ~85 | ~85 |

| Power input(V) | 3-phase AC200(50Hz/60Hz) | 3-phase AC200(50Hz/60Hz) |

| Power equipment capacity(VA) | 230 | 230 |

| Current consumption(A) | 1.15 | 1.15 |

| Motor | Geared motor 0.2KW-3P, grounded | Geared motor 0.2KW-3P, grounded |

| Rotating cutter |

98mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

98mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

| Press moving cutter |

2.1mm × 3.5mm 24pcs ・75cycles/min (50Hz) ・90cycles/min (60Hz) |

2.1mm × 3.5mm 24pcs ・75cycles/min (50Hz) ・90cycles/min (60Hz) |

| Mouth on main body(mm) | 120 × 120 | 120 × 120 |

| Hopper throat(mm) | 120 × 120 | 120 × 120 |

| Material tank volume(ℓ) | 6(3kg) | 6(3kg) |

| Cuttable sprue diameter(mm) | φ 6mm or smaller | φ 6mm or smaller |

| Processing capacity | Intermittent feeding, 30 through 40g max. per minute | Intermittent feeding, 30 through 40g max. per minute |

| Machine weight(kg) | 60 | 65 |

| SPCⅡ-C200 | SPCⅡ-C200 |

*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

SPCⅡ-C400/SPCⅡ-C400S

Option Magnetic Bar、Hopper with Anti-Scatter Shutter、Safety Hopper (Z type)、Safety Hopper (Z type)、Signal Tower、Auxiliary Chute、Buzzer、Paper Bag Frame、Suction Tank、Emergency stop button| SPCⅡ-C400 | SPCⅡ-C400S | |

|---|---|---|

| Place of operation | Indoor | Indoor |

| Ambient temperature(℃) | -10~+40 | -10~+40 |

| Ambient humidity(%) | ~85 | ~85 |

| Power input(V) | 3-phase AC200(50Hz/60Hz) | 3-phase AC200(50Hz/60Hz) |

| Power equipment capacity(VA) | 430 | 430 |

| Current consumption(A) | 2.15 | 2.15 |

| Motor | Geared motor 0.2KW-3P, grounded | Geared motor 0.2KW-3P, grounded |

| Rotating cutter |

98mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

98mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

| Press moving cutter |

2.1mm × 3.5mm 24pcs ・75cycles/min (50Hz) ・90cycles/min (60Hz) |

2.1mm × 3.5mm 24pcs ・75cycles/min (50Hz) ・90cycles/min (60Hz) |

| Mouth on main body(mm) | 162 × 162 | 162 × 162 |

| Hopper throat(mm) | 200 × 162 | 200 × 162 |

| Material tank volume(ℓ) | - | - |

| Cuttable sprue diameter(mm) | φ 6mm or smaller | φ 6mm or smaller |

| Processing capacity | Intermittent feeding, 30 through 40g max. per minute | Intermittent feeding, 30 through 40g max. per minute |

| Machine weight(kg) | 95 | 100 |

| SPCⅡ-C400 | SPCⅡ-C400S |

*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

SPCⅢ-C750/SPCⅢ-C750S

TOTAL LINK (optional)

Connect with Total Link to monitor Gran Cutter's operation and shutdown.It also helps to improve productivity by detecting bridged of sprue and runner.

| SPCⅢ-C750 | SPCⅢ-C750S | |

|---|---|---|

| Power input(V) | 3-phase AC200(50Hz/60Hz) | 3-phase AC200(50Hz/60Hz) |

| Motor | 0.75kw‐4P | 0.75kw‐4P |

| Rated current(A) | 3.2A/3.0A | 3.2A/3.0A |

| Rotating blade |

φ176mm,4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

φ176mm,4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

| Press moving cutter |

2.8mm × 4.5mm 35pcs 150cycles/min (50Hz)・180cycles/min (60Hz) |

2.8mm × 4.5mm 35pcs 150cycles/min (50Hz)・180cycles/min (60Hz) |

| Mouth on main body(mm) | 211 × 330 | 211 × 330 |

| Hopper throat(mm) | 285 × 332 | 285 × 332 |

| Material tank volume | 6ℓ | 6ℓ |

| Cuttable sprue diameter(mm) | φ 8mm or smaller | φ 8mm or smaller |

| Intermittent feeding, 30 through 40g max. per minute | 150~200g | 150~200g |

| Machine weight(kg) | 168 | 173 |

| SPCⅢ-C750 | SPCⅢ-C750S |

* The weight of material stored in the bin varies depending on the material type

* The hard type Gran cutter's processing capacity is the measured value when cutting the sprue; 6-nylon with 20% glass fiber, max. 6 mm diameter and 4g-weight

* The soft type Gran cutter's processing capacity is the measured value when cutting the sprue; thermoplastic elastomer, max. 6 mm diameter and 3g-weight

SPCⅢ-1500/SPCⅢ-1500S

| SPCⅢ-1500/SPCⅢ-1500S | Option | |

|---|---|---|

| Power input(V) | 3-phase AC200(50Hz/60Hz) | null |

| Motor | 0.75kw‐4P | null |

| Rated current(A) | 6.4A / 6.0A | null |

| Rotating blade | φ220mm 4 pcs, 20mm thick | null |

| Press moving cutter | Standard size blade : 3.8mm x 6mm, 42 pcs | Optional small size blade : 2.8mm×4.5mm, 56pcs |

| Mouth on main body(mm) | 337mm (length) x 330mm (width) | |

| Hopper throat(mm) | 374mm (length) x 332mm (width) | |

| Cuttable sprue diameter(mm) | Standard size blade 13mm or less | Optional small size blade 8mm or less |

| Processing capacity ※ |

Standard size blade (hard type): 547-684g/min Standard size blade (soft type): 523-654g/min |

Optional small size blade (hard type): 320-400g/min Optional small size blade (soft type): 302-378g/min |

| Hopper direction selection | Two directions (motor side, side plate side) | null |

| Material tank volume | 9ℓ | |

| Operating noise | Max. 69.7dB (A) (before loading) | null |

| Machine weight(kg) | 289kg | 285kg for the optional small size blade (hard type) | |

| SPCⅢ-1500/SPCⅢ-1500S | Option |

※ The model for hard material: The figures are calculated based on sprues of nylon 6 resin with 20% glass fiber, max. 6 mm in dia., 2.9 g in weight, 48 mm in width, and 94 mm in length.

※The model for soft material: The figures are calculated based on sprues of elastomer with max. 6.6 mm in dia., 2.4 g in weight, 22 mm in width, and 88 mm in length.

SPCⅡ-1500/SPCⅡ-1500S

Standard : Cleaning awl, Suction material tank for level gauge, Machine stops when level gauge material is full

Options: Press blade 6m/m, Material tank

| SPCⅡ-1500 | SPCⅡ-1500S | |

|---|---|---|

| Place of operation | Indoor | Indoor |

| Ambient temperature(℃) | -10~+40 | -10~+40 |

| Ambient humidity(%) | ~85 | ~85 |

| Power input(V) | 3-phase AC200(50Hz/60Hz) | 3-phase AC200(50Hz/60Hz) |

| Power equipment capacity(VA) | 1330 | 1330 |

| Current consumption(A) | 6.15 | 6.15 |

| Motor | Geared motor 0.2KW-3P, grounded | Geared motor 0.2KW-3P, grounded |

| Rotating cutter |

φ220mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

φ220mm diam, 4pcs (37.5rpm/50Hz ・45rpm/60Hz) |

| Press moving cutter |

3.8mm × 6mm 45pcs ・112.5cycles/min (50Hz) ・135cycles/min (60Hz) |

3.8mm × 6mm 45pcs ・112.5cycles/min (50Hz) ・135cycles/min (60Hz) |

| Mouth on main body(mm) | 360 × 360 | 360 × 360 |

| Hopper throat(mm) | 402 × 360 | 402 × 360 |

| Material tank volume(ℓ) | 9(4kg) | 9(4kg) |

| Cuttable sprue diameter(mm) | φ 13mm or smaller | φ 13mm or smaller |

| Processing capacity | Intermittent feeding, 320 through 400g max. per minute | Intermittent feeding, 320 through 400g max. per minute |

| Machine weight(kg) | 295 | 295 |

| SPCⅡ-1500 | SPCⅡ-1500S |

*The hard type Gran-Cutter's processing capacity is the measured value when cutting the sprues; 6-nylon with 20% glass fiber, 6mm-max diameter, 4g-weight.

*The soft type Gran-Cutter's processing capacity is the measured value when cutting the sprues; thermoplastic elastomer, 6mm-max diameter, 3g-weight.

Other Gran Cutter / Mixer

New Information about this product

No articles found.

No articles found.

No articles found.

No articles found.

About us

Company name

HARMO Co., Ltd.

Business Activities

Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts) and streamlined auxiliary machines for plastic molding machine

Address

4124-1 Minamiminowa-mura Kamiina-gun Nagano, Japan 399-4595

Phone

+81-265-73-8820

International Marketing Department

- Address 4124-1 Minamiminowa-mura Kamiina-gun Nagano, 399-4595

- TEL : 0265-73-8820

- FAX : 0265-73-8964

- E-mail : kaigai@harmo-net.co.jp

- Sales Office (Subsidiary) Singapore, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America

- Factory Suzhou

Sales Office (Subsidiary)

SINGAPORE

HARMO CO.,(SINGAPORE) PTE., LTD.

23TAGORE LANE #01-03 TAGORE 23 WAREHOUSE

SINGAPORE 787601

- TEL : +65-6481-1764

- FAX : +65-6481-6130

- E-mail : general@harmo.com.sg

INDONESIA

Festival Boulevard Blok AA 11 No61 Grand Wisata Desa Lambangsari Kec. Tambun-Selatan Kab. Bekasi 17510

- TEL : 021-8262-1667 / 68

- FAX : 021-8262-1726

- E-mail : hiro-tsuchiya@harmo-net.co.jp

MALAYSIA

HARMO CO., (MALAYSIA) SDN. BHD.

LOT 0034, KOMPLEKS SENTRAL No.33, JALAN SEGAMBUT

ATAS 51200 KUALA LUMPUR MALAYSIA

- TEL : +60-3-6251-2057

- E-mail : t_osaki@harmo-net.co.jp

Penang Office

HARMO CO., (MALAYSIA) SDN. BHD.

No.10, GROUND FLOOR JALAN PERAI JAYA 6, BANDAR BARU

PERAI JAYA, 13700 PERAI PENANG MALASIA

- TEL : +60-4-3972057

- E-mail : t_osaki@harmo-net.co.jp

THAILAND

HARMO (THAILAND) LTD.

410/71-72 SOI RATCHADAPISEK 24,RATCHADAPISEK RD., SAMSENNORK,HUAY-KWANG, BANGKOK 10310

- TEL : +66-2-541-4287

- FAX : +66-2-541-4286

- E-mail : t_nakazawa@harmo-net.co.jp

SHENZHEN

HARMO MACHINERY (SHENZHEN) CO., LTD.

Room 8213, JinBao business building, 15 Shun Feng Road, 44 District,AnLe Community, Xin’an street, Baoan District, Shenzhen. China

- TEL : (+86) 755-88868177

- FAX : (+86) 755-83862500

- E-mail : szoffice@harmo-net.com

SHANGHAI

HARMO MACHINERY (SHANGHAI) CO., LTD.

Room 805, North Tower,Guanghua Building, 870 Maotai Road, Changning District,Shanghai

- TEL : +86-21-80199227

- FAX : +86-21-80199228

- E-mail : harmosh@harmo-net.com

Dalian Office

Room 1005, Gugeng International Hotel, No.138, Jinma Road, Dalian P.R. China 116600

- TEL : (0411)87962819

- FAX : (0411)87962819

Tianjin Office

Room 323,Yunhan Building,No.185,Qinjian Road,Hongqiao District,Tianjin 300130

- TEL : (022)87355626

- FAX : (022)87355626

Xiamen Office

Room B415, Xinxinjingdi Building, No.396, Jiahe Road, Huli District, Xiamen

- TEL : 0592-3233250

- FAX : 0592-3233250

HOCHIMINH Office

Harmo America inc.

2675 American Lane Elk Grove Village IL 60007

- TEL : +1-630-594-4116

- URL : www.harmo-america.com

SUZHOU

HARMO (SUZHOU) CO., LTD.

NO.15 XIANGPU ROAD, SHENGPU TOWN, SUZHOU INDUSTRIAL PARK, SUZHOU

- TEL : (+86) 512-6295-5112

- FAX : (+86) 512-6295-5117

- URL : www.harmo.com.cn/

Global agency

Korea

HANSE KOREA Co., Ltd.

#503,DAERUNG TECHNOTOWN 7CHA,489-11 GASAN-DONG,GEUMCI-KU,SEOUL,KOREA

- TEL: +82-2-2108-4511〜9

- FAX: +82-2-2108-4510

- URL: http://han-se.com

Philippines

NPI Machinery Inc

5th Floor Orcel II Bldg. 1611 Quezon Avenue, West Triangle, Quezon City, 1100 Philippines

- TEL: (632)926-7479

- FAX: (632)920-3096

Taiwan

XIN JU AUTOMACHINE CORP.

NO.25,Changchun 6th Rd., Zhongli Dist., Taoyuan City 320, Taiwan(R.O.C)

- TEL:886-3-4623797

- FAX:886-3-4622397

Australia

Cam-Plas Machinery Pty. Ltd.

2/30 Catherine Street, Coburg North, VICTORIA, Australia, 3058

- TEL: +61-3-9355-7099

New Zealand

TCL Hunt Limited.

7 Fisher Crescent Mount Wellington Auckland 1060 PO Box 132-166 Sylvia Park Auckland 1644 New Zealand

- TEL: +64-9-526-2700

- FAX: +64-9-525-0875

- URL: https://tclhunt.co.nz/

Brazil

Hercx Representação de Máquinas e Equipamentos Plásticos Ltda

Alameda Princesa Isabel, 654 – São Bernardo do Campo – São Paulo, CEP 09771-110, Brazil

- TEL: +55 11 2677-3040

- MOBILE: +55 11 99898-6066

- E-mail: hercules@hercx.net

Mexico

Otakara PLASTICOS

Jeronimo Trevino 3835 Col. Lopez Portillo Guadalajara, Jalisco, Mexico C.P. 44980

- TEL: +52-(33)-3663-9798

- FAX: +52-(33)-3646-2364

- URL: http://www.otakaraplasticos.com/

Israel

Multipack

3, Derech Hyam St. P.O. Box 376 81103 Yavne Israel

- TEL: +972-8942-7325

- FAX: +972-8942-0397

Italy

STAGE TECHNOLOGIES

ST.A.TE Technologies Srl Vail Vailate 15 / A、24040-Calvenzano(BG)

- TEL: 0363 8535209

- FAX: 0363 853115

- URL: http://www.state-tech.it/

Poland

HARMO REPRESENTATIVE POLAND & EAST EUROPE

ul. Kazimierza Pułaskiego 2 64-600 Oborniki

- TEL: +48-608-489-327

- E-mail: ds@darsta.pl

- URL: https://www.darsta.pl/

INDIA

KANEHIRO YANTRA PRIVATE LIMITED

Flat No 22, krishna Apartment, No.59, 1st Avenue, Ashok Nagar, Chennai – 600 083, Tamil Nadu, India.

- TEL: +91 (44) 4856-7520

- MOBILE: +91 (98) 8405-7520

- E-mail: keshavan@kanehiro.co.in

- URL: https://www.kanehiro.co.in/

.jpg?width=500&height=500&name=%E8%B6%85%E5%A4%A7%E5%9E%8B%E4%BB%95%E6%A7%98%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%20(1).jpg)

%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg?width=500&height=500&name=_%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC(%E4%BD%9C%E8%A3%BD%E4%BE%8B)%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg)

.jpg?width=500&height=500&name=%E5%90%B8%E7%9D%80%E3%83%91%E3%83%83%E3%83%88%E3%81%AE%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=%E3%83%AF%E3%83%B3%E3%82%BF%E3%83%83%E3%83%81%E3%82%A2%E3%82%BF%E3%83%83%E3%83%81%E3%83%A1%E3%83%B3%E3%83%88%7C%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC%20(%E5%8F%96%E5%87%BA%E6%A9%9F%E5%81%B4)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=HC15BPX%7C%E3%83%AC%E3%83%90%E3%83%BC%E3%83%81%E3%83%A3%E3%83%83%E3%82%AF(%E3%83%95%E3%82%A3%E3%83%B3%E3%82%AC%E3%83%BC%E3%83%84%E3%83%BC%E3%83%AB%E4%BB%98)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)