MVA series

Series that responds flexibly to needs

You can choose according to the molding site.

- A type that repeats start/stop by a timer.

- A type that is activated when the counter counts up.

- A type that is activated by an external signal and stops by timer

Product PDF

Product features

Aluminum Frame

High-precision aluminum extrusion with slit (groove) structure for easy attachment. Its structure reduces distortion on the frame over the long term use.

Meander-less type belt (option)

A meandless type that reduces belt meandering.

Belts

Angle adjustment as desired

The angle can be easily adjusted as desired within the range of the adjuster.

Single Pole Stand (option)

- M-leg adjustment range (mm) 810~1320

- L-leg adjustment range (mm) 1110~1920

Adjustable Leg (option)

- No.1 leg adjustment range (mm) 770~1090)

- No.2 leg adjustment range (mm) 980~1380)

- No. 3 leg adjustment range (mm) 1280~1680

- No. 4 leg adjustment range (mm) 1580~1980

Control box

In addition to the standard control box, control boxes with additional options "TS type", "TH type", "CTS type", "LT type", "BC type", "BSS type", "BTSS type", and "BCSS type" are available.

Wide variety of gear heads available (optional)

Wide variety of gear heads are available (optional). You can choose the most suitable gear head for your belt speed.

Operation Panel

-

User-friendly interface

-

Smooth operations with the equipped touch panel.

- Error/alarm display

Option (Select a controller box type.)

Conveyor for continuous operation which can change the belt drive speed within the adjustment range.

(ON-OFF Timer) The conveyor runs and stops repeatedly according to the settings of the ON-OFF timers.

Product Specifications

MVA series(Motor Conveyor)

| Weight (kg) | Length (mm) | Width (mm) | Belt Width (mm) | Belt Length (mm) | |

|---|---|---|---|---|---|

| MVA- 20-1(R) | 26 | 1070 | 320 | 200 | 2210 |

| MVA- 20-1.5(R) | 31 | 1570 | 320 | 200 | 3210 |

| MVA- 20-2(R) | 35 | 2070 | 320 | 200 | 4210 |

| MVA- 20-2.5(R) | 42 | 2570 | 320 | 200 | 5210 |

| MVA- 20-3(R) | 50 | 3570 | 320 | 200 | 7210 |

| MVA- 20-3.5(R) | 50 | 3570 | 320 | 200 | 7210 |

| MVA- 20-4(R) | 57 | 4070 | 320 | 200 | 8210 |

| MVA- 20-4.5(R) | 68 | 4570 | 320 | 200 | 9210 |

| MVA- 20-5(R) | 79 | 5070 | 320 | 200 | 10210 |

| MVA- 30-1(R) | 28 | 1070 | 420 | 300 | 2210 |

| MVA- 30-1.5(R) | 33 | 1570 | 420 | 300 | 3210 |

| MVA- 30-2(R) | 46 | 2070 | 420 | 300 | 4210 |

| MVA- 30-2.5(R) | 54 | 2570 | 420 | 300 | 5210 |

| MVA- 30-3(R) | 62 | 3070 | 420 | 300 | 6210 |

| MVA- 30-3.5(R) | 68 | 3570 | 420 | 300 | 7210 |

| MVA- 30-4(R) | 74 | 4070 | 420 | 300 | 8210 |

| MVA- 30-4.5(R) | 83 | 4570 | 420 | 300 | 9210 |

| MVA- 30-5(R) | 94 | 5070 | 420 | 300 | 10210 |

| MVA- 40-1(R) | 34 | 1070 | 520 | 400 | 2210 |

| MVA- 40-1.5(R) | 39 | 1570 | 520 | 400 | 3210 |

| MVA- 40-2(R) | 54 | 2070 | 420 | 300 | 4210 |

| MVA- 40-2.5(R) | 60 | 2570 | 420 | 300 | 5210 |

| MVA- 40-3(R) | 68 | 3070 | 520 | 400 | 6210 |

| MVA- 40-3.5(R) | 74 | 3570 | 520 | 400 | 7210 |

| MVA- 40-4(R) | 79 | 4070 | 520 | 400 | 8210 |

| MVA- 40-4.5(R) | 91 | 4570 | 520 | 400 | 9210 |

| MVA- 40-5(R) | 104 | 5070 | 520 | 400 | 10210 |

| MVA- 50-1(R) | 41 | 1070 | 620 | 500 | 2210 |

| MVA- 50-1.5(R) | 47 | 1570 | 620 | 500 | 3210 |

| MVA- 50-2(R) | 61 | 2070 | 620 | 500 | 4210 |

| MVA- 50-2.5(R) | 69 | 2570 | 620 | 500 | 5210 |

| MVA- 50-3(R) | 76 | 3070 | 620 | 500 | 6210 |

| MVA- 50-3.5(R) | 82 | 3570 | 620 | 500 | 7210 |

| MVA- 50-4(R) | 88 | 4070 | 620 | 500 | 8210 |

| MVA- 50-4.5(R) | 101 | 4570 | 620 | 500 | 9210 |

| MVA- 50-5(R) | 114 | 5070 | 620 | 500 | 10210 |

| MVA- 60-1(R) | 49 | 1070 | 720 | 600 | 2210 |

| MVA- 60-1.5(R) | 55 | 1570 | 720 | 600 | 3210 |

| MVA- 60-2(R) | 69 | 2070 | 720 | 600 | 4210 |

| MVA- 60-2.5(R) | 77 | 2570 | 720 | 600 | 5210 |

| MVA- 60-3(R) | 81 | 3070 | 720 | 600 | 6210 |

| MVA- 60-3.5(R) | 90 | 3570 | 720 | 600 | 7210 |

| MVA- 60-4(R) | 100 | 4070 | 720 | 600 | 8210 |

| MVA- 60-4.5(R) | 113 | 4570 | 720 | 600 | 9210 |

| MVA- 60-5(R) | 126 | 5070 | 720 | 600 | 10210 |

| Weight (kg) | Length (mm) | Width (mm) | Belt Width (mm) | Belt Length (mm) |

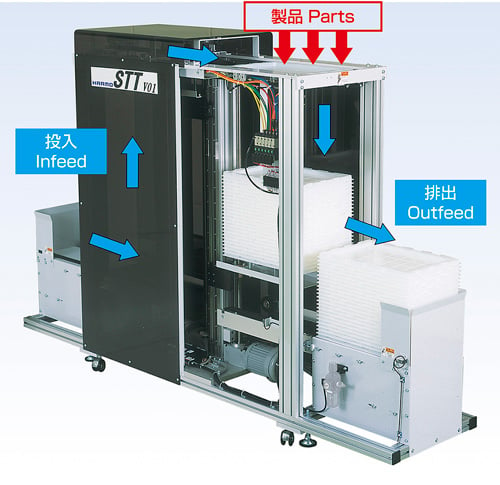

- STP-V01

-

- Standard model

- Payload 10kg

- Box change time: 15 sec.

- STP-V02

-

- Latest version of standard model

- Payload 7kg

- Box change time: 8 sec.

- STH-V01

-

- High-cycle

- Conveyor total payload 100 kg

- Box change time: 9 sec.

- STR-V01

-

- High cycle return type

- Payload 4kg

- Box change time: 8 sec.

- HCSⅡ-25

-

- Belt conveyor type box filling system

- Box change time: 15 sec.

- Total payload of conveyor section 10kg

- Customizable Box Filling System

-

- Tray stocker

- Palletizing stocker

- Double deck filling system

- STP-V01 M type specifications

New Information about this product

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

About us

Company name

HARMO Co., Ltd.

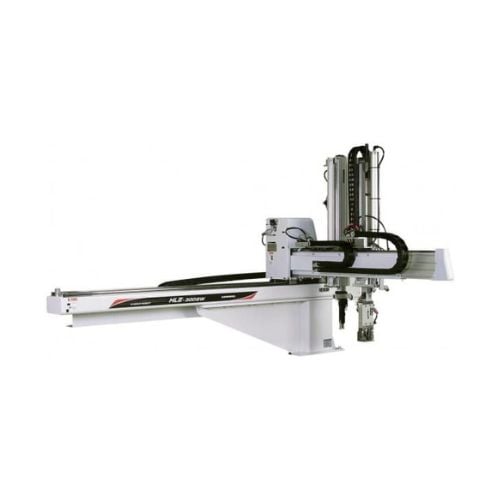

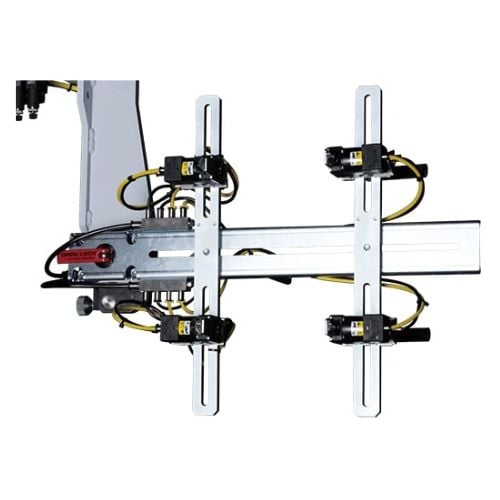

Business Activities

Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts) and streamlined auxiliary machines for plastic molding machine

Address

4124-1 Minamiminowa-mura Kamiina-gun Nagano, Japan 399-4595

Phone

+81-265-73-8820

International Marketing Department

- Address 4124-1 Minamiminowa-mura Kamiina-gun Nagano, 399-4595

- TEL : 0265-73-8820

- FAX : 0265-73-8964

- E-mail : kaigai@harmo-net.co.jp

- Sales Office (Subsidiary) Singapore, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America

- Factory Suzhou

Sales Office (Subsidiary)

SINGAPORE

HARMO CO.,(SINGAPORE) PTE., LTD.

23TAGORE LANE #01-03 TAGORE 23 WAREHOUSE

SINGAPORE 787601

- TEL : +65-6481-1764

- FAX : +65-6481-6130

- E-mail : general@harmo.com.sg

INDONESIA

Festival Boulevard Blok AA 11 No61 Grand Wisata Desa Lambangsari Kec. Tambun-Selatan Kab. Bekasi 17510

- TEL : 021-8262-1667 / 68

- FAX : 021-8262-1726

- E-mail : hiro-tsuchiya@harmo-net.co.jp

MALAYSIA

HARMO CO., (MALAYSIA) SDN. BHD.

LOT 0034, KOMPLEKS SENTRAL No.33, JALAN SEGAMBUT

ATAS 51200 KUALA LUMPUR MALAYSIA

- TEL : +60-3-6251-2057

- E-mail : t_osaki@harmo-net.co.jp

Penang Office

HARMO CO., (MALAYSIA) SDN. BHD.

No.10, GROUND FLOOR JALAN PERAI JAYA 6, BANDAR BARU

PERAI JAYA, 13700 PERAI PENANG MALASIA

- TEL : +60-4-3972057

- E-mail : t_osaki@harmo-net.co.jp

THAILAND

HARMO (THAILAND) LTD.

410/71-72 SOI RATCHADAPISEK 24,RATCHADAPISEK RD., SAMSENNORK,HUAY-KWANG, BANGKOK 10310

- TEL : +66-2-541-4287

- FAX : +66-2-541-4286

- E-mail : t_nakazawa@harmo-net.co.jp

SHENZHEN

HARMO MACHINERY (SHENZHEN) CO., LTD.

Room 8213, JinBao business building, 15 Shun Feng Road, 44 District,AnLe Community, Xin’an street, Baoan District, Shenzhen. China

- TEL : (+86) 755-88868177

- FAX : (+86) 755-83862500

- E-mail : szoffice@harmo-net.com

SHANGHAI

HARMO MACHINERY (SHANGHAI) CO., LTD.

Room 805, North Tower,Guanghua Building, 870 Maotai Road, Changning District,Shanghai

- TEL : +86-21-80199227

- FAX : +86-21-80199228

- E-mail : harmosh@harmo-net.com

Dalian Office

Room 1005, Gugeng International Hotel, No.138, Jinma Road, Dalian P.R. China 116600

- TEL : (0411)87962819

- FAX : (0411)87962819

Tianjin Office

Room 323,Yunhan Building,No.185,Qinjian Road,Hongqiao District,Tianjin 300130

- TEL : (022)87355626

- FAX : (022)87355626

Xiamen Office

Room B415, Xinxinjingdi Building, No.396, Jiahe Road, Huli District, Xiamen

- TEL : 0592-3233250

- FAX : 0592-3233250

HOCHIMINH Office

Harmo America inc.

2675 American Lane Elk Grove Village IL 60007

- TEL : +1-630-594-4116

- URL : www.harmo-america.com

SUZHOU

HARMO (SUZHOU) CO., LTD.

NO.15 XIANGPU ROAD, SHENGPU TOWN, SUZHOU INDUSTRIAL PARK, SUZHOU

- TEL : (+86) 512-6295-5112

- FAX : (+86) 512-6295-5117

- URL : www.harmo.com.cn/

Global agency

Korea

HANSE KOREA Co., Ltd.

#503,DAERUNG TECHNOTOWN 7CHA,489-11 GASAN-DONG,GEUMCI-KU,SEOUL,KOREA

- TEL: +82-2-2108-4511〜9

- FAX: +82-2-2108-4510

- URL: http://han-se.com

Philippines

NPI Machinery Inc

5th Floor Orcel II Bldg. 1611 Quezon Avenue, West Triangle, Quezon City, 1100 Philippines

- TEL: (632)926-7479

- FAX: (632)920-3096

Taiwan

XIN JU AUTOMACHINE CORP.

NO.25,Changchun 6th Rd., Zhongli Dist., Taoyuan City 320, Taiwan(R.O.C)

- TEL:886-3-4623797

- FAX:886-3-4622397

Australia

Cam-Plas Machinery Pty. Ltd.

2/30 Catherine Street, Coburg North, VICTORIA, Australia, 3058

- TEL: +61-3-9355-7099

New Zealand

TCL Hunt Limited.

7 Fisher Crescent Mount Wellington Auckland 1060 PO Box 132-166 Sylvia Park Auckland 1644 New Zealand

- TEL: +64-9-526-2700

- FAX: +64-9-525-0875

- URL: https://tclhunt.co.nz/

Brazil

Hercx Representação de Máquinas e Equipamentos Plásticos Ltda

Alameda Princesa Isabel, 654 – São Bernardo do Campo – São Paulo, CEP 09771-110, Brazil

- TEL: +55 11 2677-3040

- MOBILE: +55 11 99898-6066

- E-mail: hercules@hercx.net

Mexico

Otakara PLASTICOS

Jeronimo Trevino 3835 Col. Lopez Portillo Guadalajara, Jalisco, Mexico C.P. 44980

- TEL: +52-(33)-3663-9798

- FAX: +52-(33)-3646-2364

- URL: http://www.otakaraplasticos.com/

Israel

Multipack

3, Derech Hyam St. P.O. Box 376 81103 Yavne Israel

- TEL: +972-8942-7325

- FAX: +972-8942-0397

Italy

STAGE TECHNOLOGIES

ST.A.TE Technologies Srl Vail Vailate 15 / A、24040-Calvenzano(BG)

- TEL: 0363 8535209

- FAX: 0363 853115

- URL: http://www.state-tech.it/

Poland

HARMO REPRESENTATIVE POLAND & EAST EUROPE

ul. Kazimierza Pułaskiego 2 64-600 Oborniki

- TEL: +48-608-489-327

- E-mail: ds@darsta.pl

- URL: https://www.darsta.pl/

INDIA

KANEHIRO YANTRA PRIVATE LIMITED

Flat No 22, krishna Apartment, No.59, 1st Avenue, Ashok Nagar, Chennai – 600 083, Tamil Nadu, India.

- TEL: +91 (44) 4856-7520

- MOBILE: +91 (98) 8405-7520

- E-mail: keshavan@kanehiro.co.in

- URL: https://www.kanehiro.co.in/

.jpg?width=500&height=500&name=%E8%B6%85%E5%A4%A7%E5%9E%8B%E4%BB%95%E6%A7%98%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%20(1).jpg)

%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg?width=500&height=500&name=_%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC(%E4%BD%9C%E8%A3%BD%E4%BE%8B)%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg)

.jpg?width=500&height=500&name=%E5%90%B8%E7%9D%80%E3%83%91%E3%83%83%E3%83%88%E3%81%AE%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=%E3%83%AF%E3%83%B3%E3%82%BF%E3%83%83%E3%83%81%E3%82%A2%E3%82%BF%E3%83%83%E3%83%81%E3%83%A1%E3%83%B3%E3%83%88%7C%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC%20(%E5%8F%96%E5%87%BA%E6%A9%9F%E5%81%B4)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=HC15BPX%7C%E3%83%AC%E3%83%90%E3%83%BC%E3%83%81%E3%83%A3%E3%83%83%E3%82%AF(%E3%83%95%E3%82%A3%E3%83%B3%E3%82%AC%E3%83%BC%E3%83%84%E3%83%BC%E3%83%AB%E4%BB%98)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

.jpg?width=1600&height=900&name=MVA%20%E3%82%B7%E3%83%AA%E3%83%BC%E3%82%BA%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)